Industrial IoT and the World of Connected Manufacturing

We live in a highly connected world today, where most of the connections aren’t obvious to us. Connected living comes as a mixed-blessing for the advantages and the risks it presents to the society. Having said that, if something needs to be rewarding, it needs to be analyzed, developed and put into all different possible uses. The advantages of having a connected system encouraged innovators to think about connected industrial machines. This in turn resulted in the birth of Industrial Internet of Things or IIoT.

Internet of Things (IoT) is a network of connected devices like intelligent computers, devices and objects which generate and share a huge amount of data. These data help with full or partial automation of our homes, schools, hospitals, work stations, and various aspects of our lives. The application of IoT to the manufacturing industry is called the IIoT (or Industrial Internet or Industry 4.0 or IR4). The industrial landscape is now witnessing a paradigm shift with the fusion of many existing technologies that are bridging the gap between the physical and digital worlds.

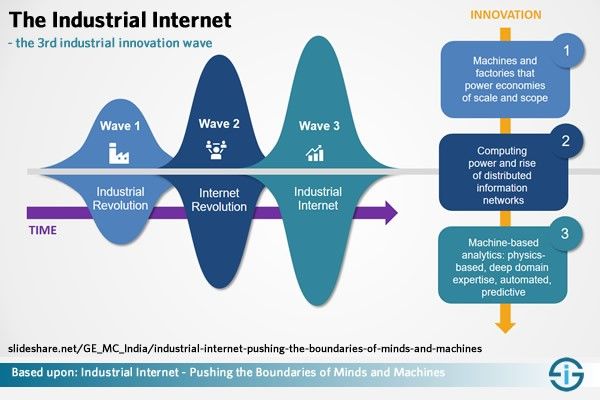

Evolution of Industrial IoT

The first Industrial Revolution (1760-1840) announced the importance of machines in the labor intensive industries which later plotted the productivity and profit graphs higher than ever before. The industries that had undergone technological and digital revolution during the late 19th and 20th centuries can be classified under the second and third industrial revolutions. The third industrial revolution that began in the 1980s, is continuing with internet, computer and robotics which created the base for a data driven and intelligent manufacturing sector.

Source: The Industrial IoT

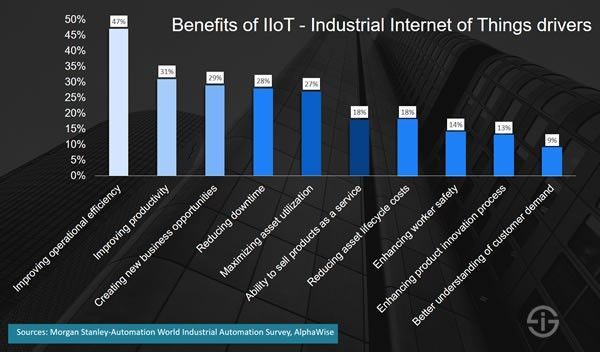

Benefits of Industrial IoT

Industrial Internet of Things enhances a production unit into a huge interconnected industrial system of machines, tools, inventory and logistics that communicates and relies on data for effective functioning. Traditionally, machine health and maintenance was pivotal for monitoring tools, whereas today, all machine parameters and statistics are generated through machines, which we call as data in general. This data is extracted, analyzed and visualized. The latest advancements in Big Data Analytics supports efficient processing of industrial data created over years and helps in obtaining deeper insights into the issues faced by these industries. Moreover, it provides a Decoupled Devices and Applications system with effective monitoring and possible predictions.

Source: The Benifits of IIOT – Industrial Internet of things

IIoT Communication: A Brief Overview

The factor defining communication is the language. In case of devices or application, the language can be termed as a ‘protocol’. There are many protocols available now, some of these are proprietary and others are known as open standards. The protocols need to be accepted and standardized by the original equipment manufacturers to support greater interoperability. However, all the protocols will co-exist—each with their own strengths and weaknesses—and it’s our job to understand where and when to use them.

The protocols can be of two types:

Client-Server: The server holds the data and the client connects and requests data from the server. Communication is possible, only if the client knows about the server in advance. Client/server protocols are best used when you understand your infrastructure.

Usage – Obtaining machine RPM or Temperature

Protocols:

OPC Unified Architecture (OPC UA) – Very secure and highly interoperable between vendors. Uses two-way message signing and transport encryption.

HTTP (REST/JSON) – Connectionless, highly accessible with minimal overhead. JSON is used as data presentation.

Constrained Application Protocol (CoAP) – Created to provide the interoperability of HTTP with minimal overhead. Uses UDP/multicast instead of TCP.

Publisher-Subscriber: Using an intermediary broker, the data will be published by the collector/producer and the consumer can subscribe and read the data. This decouples the Publisher and Subscriber as both need to know only about the broker which accepts and provides data.

Publish/subscribe protocols are a better fit when your infrastructure is unknown.

Usage – Machine RPM or Temperature sampled from different devices and published to a broker for monitoring.

Protocols:

Message Queuing Telemetry Transport (MQTT) – Designed for SCADA and remote networks, Minimal overhead, reliable communication and simple architecture.

Data Distribution Service (DDS) – Open standard, decentralized, reliable, real-time data delivery at the edge. Use it for fast M2M communications.

Advanced Message Queuing Protocol (AMQP) – Developed in financial services sector, guarantee data transactions, limited acceptance in industry, heavy protocol.

The Future

Industrial Internet of Things is crucial for any industry that demands significant improvements in safety, efficiency, and profitability. Businesses that have embraced IIoT are enjoying a remarkable advantage, and it is expected that this trend will continue as IIoT technologies are getting wider recognition and adoption. The future may also witness the unification of fragmented IIoT platforms which will emerge to be more secure and robust.

“When wireless is perfectly applied the whole earth will be converted into a huge brain, which in fact it is, all things being particles of a real and rhythmic whole. We shall be able to communicate with one another instantly, irrespective of distance” – Nikola Tesla

IoT solves many of the grave challenges faced by asset-intensive industries today. Our customers often tell us how our bespoke IoT solutions helped them overcome barriers in their industries and led them to better opportunities. If you need any expert assistance on making your business smarter with IoT, connect with us.

We can help!